SI4100 – LP

Surface Defect Inspector with Cameras and Laser for Profiles

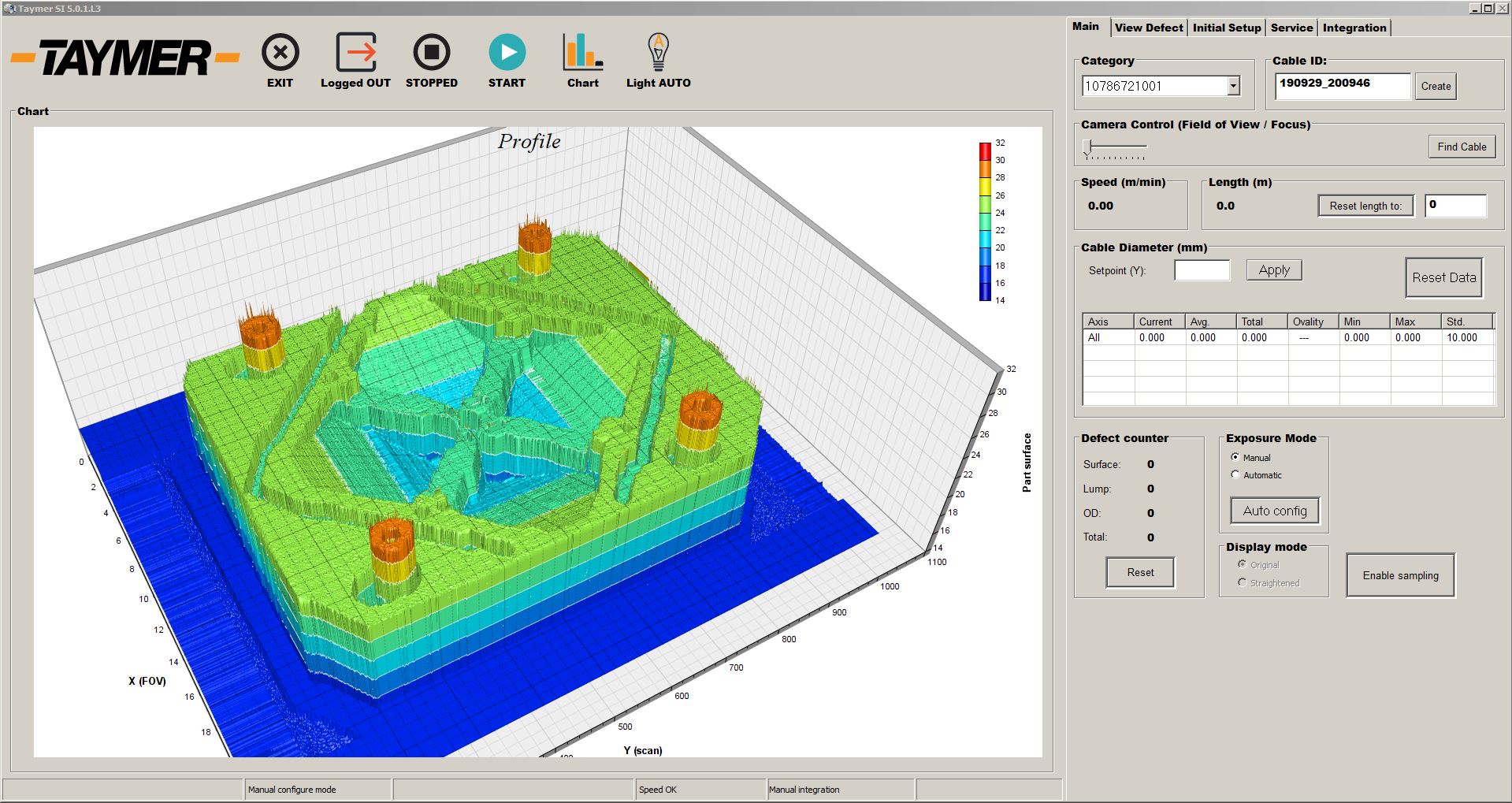

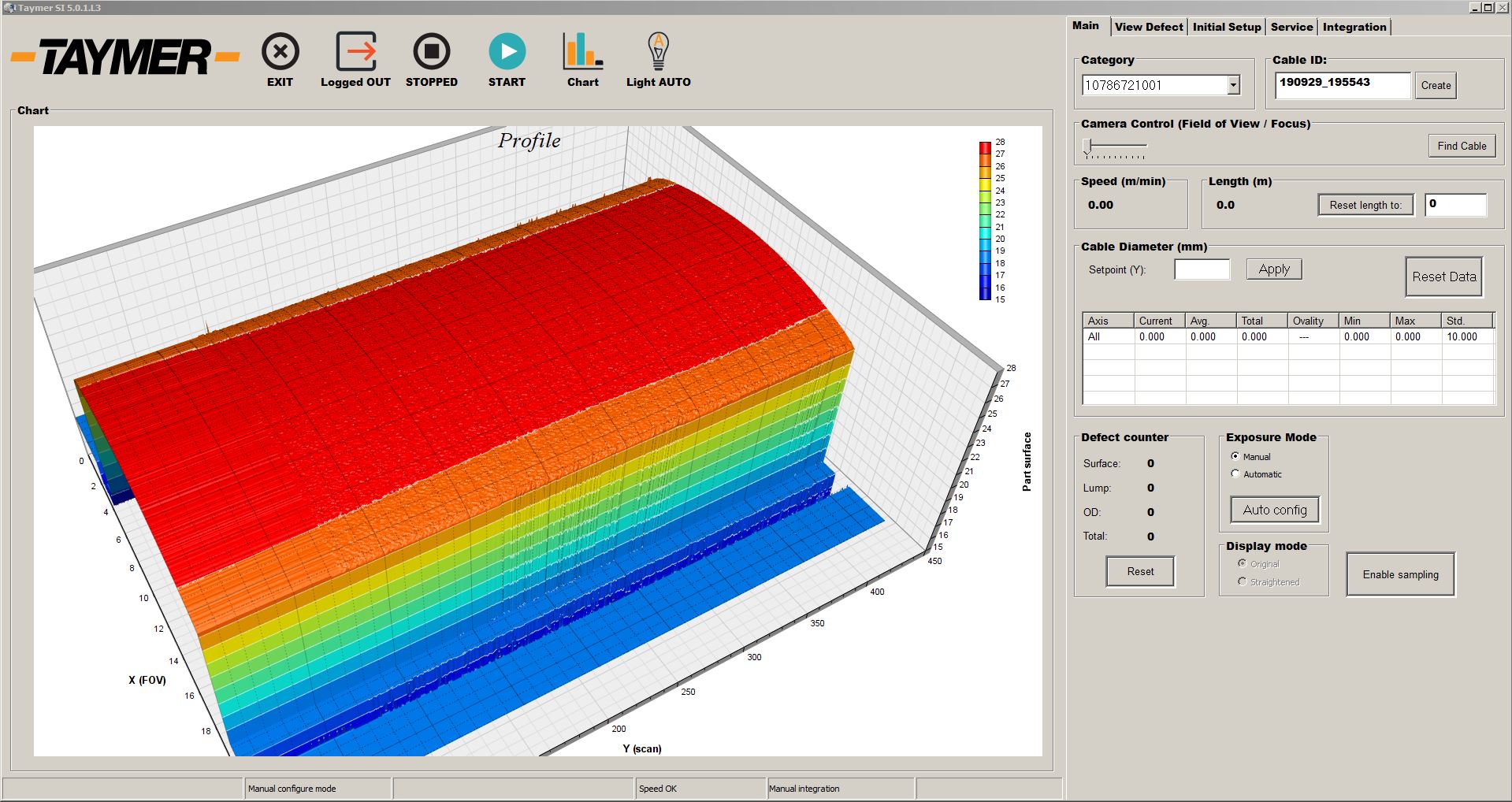

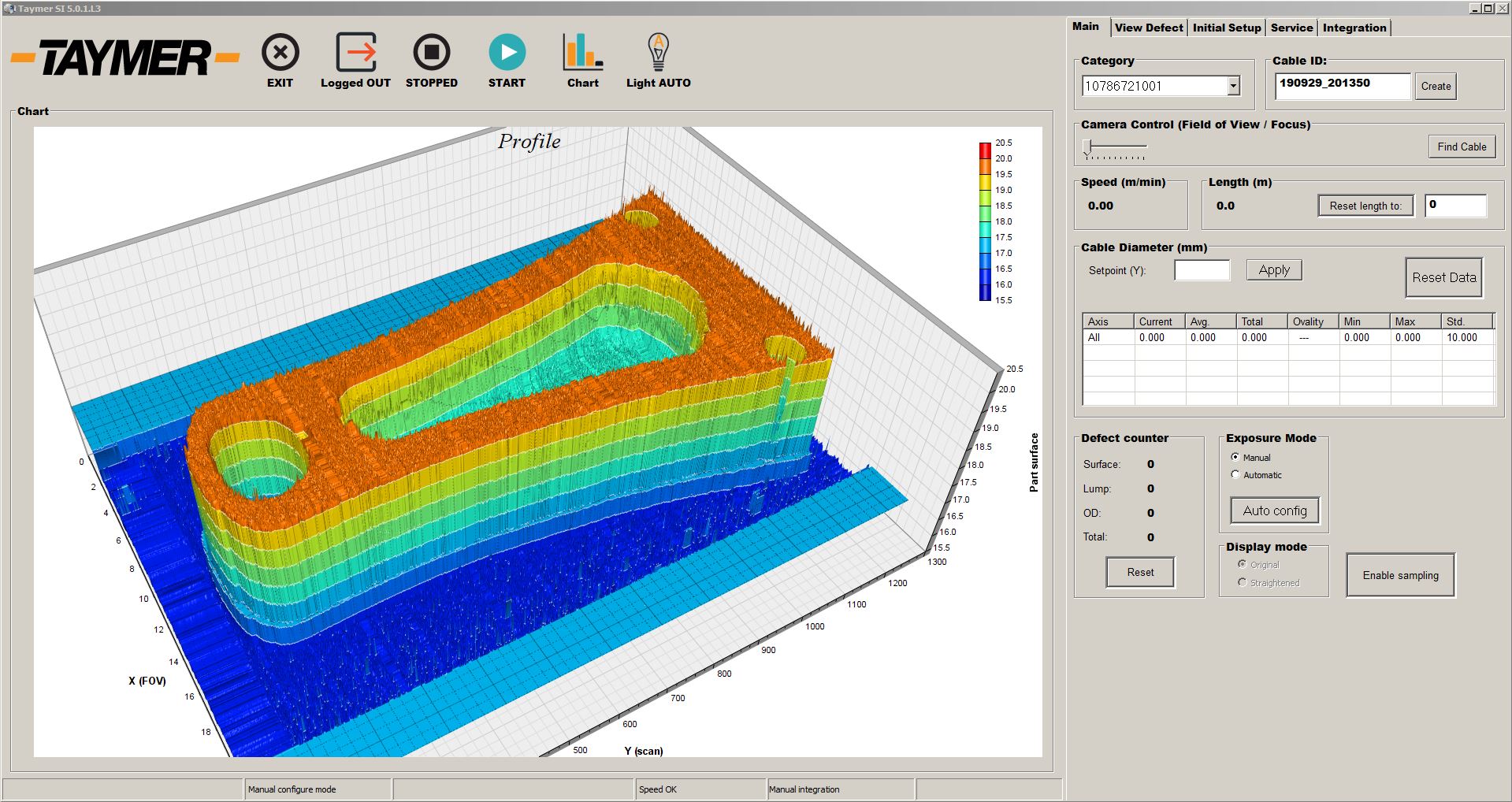

The SI4100-LP will capture, analyze, and judge every square millimeter of your product with both cameras and lasers. It is the most thorough method of detecting surface flaws available. The SI4100-LP system provides pictures of your profile as well as laser-accurate dimensional measurements of selected features. Simplify the QA process and allow your operator to see defects during your run. With the Surface Inspector, you can be sure the product you are sending to your customers is without defects and according to your company standards.

Image Feedback and QA Improvements

The SI4100-LP provides the operator with up-to the-second digital image feedback of the current product surface and dimensions on any production line. This continuous stream of real-time information allows the operator to isolate causes and locations of the imperfections on the product. This will result in reducing defects and in-turn reducing the scrapping of product, customer complaints and recalls. Defect images are also saved, so they can be included in quality reports for internal or external use.

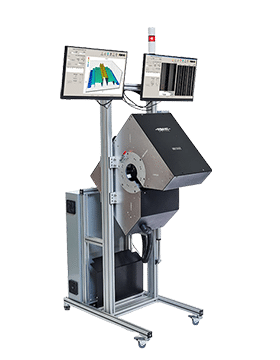

Industrial Setup, even for Dirty Environments

The SI4100-LP is designed for 24/7 operation in an industrial environment. The height-adjustable aluminum extrusion frame allows for quick and accurate line-height adjustments. A sliding rail at the base allows for lateral adjustments and provides operators with the option to slide the system out of the way so bulky products can pass through. Easy-to-clean covers and shields prevent dust particles from entering the system. Fans, lens filters, and optional air wipes are also used to keep the whole system clean and dust free.

Features

- Detects pinholes, bulges, neckdowns, surface blemishes, die cuts on cable jacket

- One-box design to fit your application’s requirements in camera and laser counts

- Dimensional readout of selected measured dimensions

- Detects defects before they reach your customer

or fail in the field - Large opening for various profiles to pass through without issue

- Height-adjustable aluminum frame, mounted on rails to easily slide system out of the way

- Height adjustable aluminum extrusion frame mounted on rails to easily slide system out of the way

- Simple and low maintenance to keep the system running 24/7

- Optional air-wipes to clean off dust & debris from profile or part before entering the system

- Alerts and records any defects into database for QA records and operator verification

- Software analyzes desired outer profile and 100% of product length

Specifications

- Maximum Line speed:

Speed will depend on application and defect requirements - Minimum detectable defect size:

0.1 mm and up | 0.004” and up

Depends on line speed and profile dimensions - Profile Size Range:

30 mm – 120 mm | 1.18” – 4.7”

Other sizes available upon request - Camera and Laser Configuration:

Configuration will depend on application requirements - Pixels/mm²:

~100 for large diameter profiles - Types of Defects Detected:

Jacket defects, pin holes, neck downs, bulges, Die Cuts, OD defects, fish eyes, discolorations, scratches or other imperfections

- Percentage Overlap Between Images:

5% - Computer and Interface:

Windows Operating System - Taymer Surface Inspection Software:

Allows for Remote Access and Database Integration - Dimensions: with stand (Custom stands can be built)

457 mm x 635 mm x 1580 mm – L x W x H

18” x 25” x 62” – L x W x H - Power Supply:

110VAC or 220VAC - Weight:

115 kg | 250 lbs. - Lighting: LED

- Image Processing:

All images from all cameras/laser are read, enhanced and analyzed, resulting in 100% product coverage at the maximum line speed