Packaging Inspection Technology for Quality Control

Now working with the packaging industry, Taymer technology is being used to control and grade label prints in-line. Our PrintView technology will check your label for any misprint, wrong or missing information as well as the quality of the ink. Taymer’s knowledge in image acquisition and software development has lead to R&D in several exciting applications seen below.

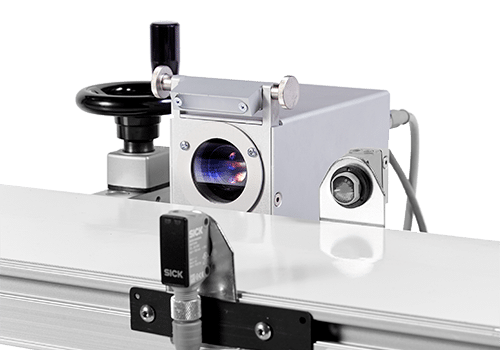

Packaging Label Verification

The PV150-PH is Taymer’s Print Verification solution for the Pharma packaging industry. This system can automatically verify the legibility of lot, expiry and serial number data printed on containers and boxes and verify them for correctness or label presence. Reduce costs by avoiding rework or recalls and improve productivity with our PV150-PH.

Cosmetics Color Verification

Inspects your product’s colour against an approved template, alerts operators if colour is out of specification and saves defective images with a time stamp for root cause analysis. Ensure your product’s colour is consistent and meets your quality standards.

Pallet Layer and Alignment Control

Verify layers are formed correctly prior to palletisation to ensure product isn’t dropped into the palletiser hoist or damaged in transport. Improve uptime, safety and prevent product damage.

Missing Package Detection in Case

Confirm the number of packages or products in a case before it reaches the consumer improving quality assurance.

Blister Pack Inspection

Verify tablets, capsules or any product used on blister packaging machines. Increase uptime, reduce false rejects and improve quality assurance.

Empty Can Inspection

Detect, reject and record defects on the base, inner side wall and flange of the can preventing damaged material from entering the filler.

Fill Level Inspection

Verify fill level, confirm bottle is capped and track when low fills are occurring. Improve quality and reduce waste.