Print Verification Equipment for Wires & Cables

Taymer camera inspection print verification is a critical print inspection tool to properly set up your wire marking equipment to free your operators from monitoring print quality. Print inspection and automated verification is critical to ensure your wire marking machines and cable meter marking machines are performing to your customer’s expectations.

Optical Character Recognition (OCR) for Enhanced Print Verification

Taymer International Incorporated is at the forefront of integrating Optical Character Recognition (OCR) technology into the wire and cable industry. By incorporating OCR into the PV1400, Taymer has revolutionized real-time quality control for the production line. This innovative approach converts print legends into a machine-readable format which can then be analyzed to assess quality, accuracy, and legibility. This technology eliminates the need for manual inspection by operators when conducting Print Verification.

The key benefits include:

- Guaranteed accuracy of print legends

- Improved traceability through the verification of date codes and sequential markings

- Instantaneous error notification without additional setup requirements for the operator

Taymer’s Optical Character Recognition features an advanced machine-learning model capable of recognizing various languages, fonts, and styles. This highly adaptable solution is suited for any printer and will perform consistently and reliably across various printing methods.

PV1400

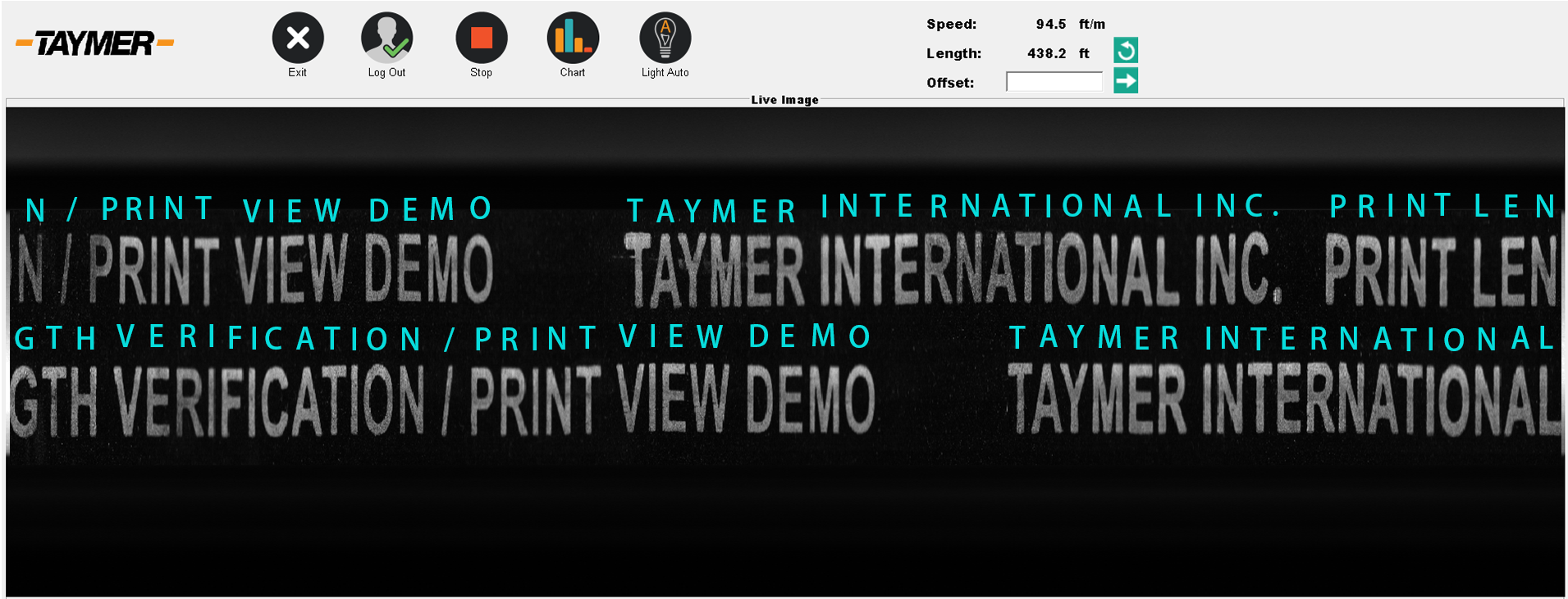

Cable and Wire Print Verification

Taymer’s Print Verification utilizes a high-speed line scan digital imaging technology to verify information printed on cable at moderately high speeds – up to 1400 feet per minute. The PV1400 can run in together with an ink wheel printer, an ink jet printer or any other high speed printing device. High Speed Surface Defect detection is a cost saving capability of the PV1400.

PLV1500

Print Length Verification

The Print Length Verification System continously monitors length marks, ensuring that your cable is marked in precise 1 meter or 2 foot increments. The PLV system offers a continuous re-calibration feedback loop that adjusts the length markings according to actual measurements on the fly. Can be integrated with both ink jet and Taymer’s Hot Foil printers.

PLV1500-S

One Axis Print Length Verification

The Print Length Verification System continously monitors length marks, ensuring that your cable is marked in precise 1 meter or 2 foot increments. The PLV system offers a continuous re-calibration feedback loop that adjusts the length markings according to actual measurements on the fly. Can be integrated with both ink jet and Taymer’s Hot Foil printers.