Sinter Cable Printing Machine

Taymer’s Sinter Printing Technology makes the most durable colored marking on wire and cable without compromising the electrical or mechanical properties of the cable. Sinter printing embeds and embosses colored powder into your cable jacket for a 100% permanent mark, ideal for highly corrosive or very abrasive environments.

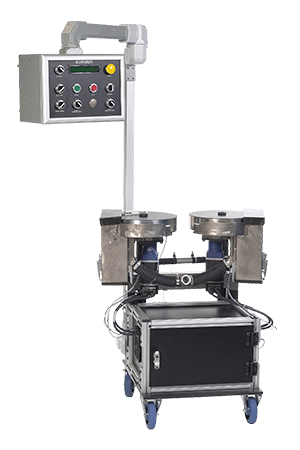

SINTER3000

Sinter Cable Printing

The Sinter 3000 will provide you with the most durable colored marking in the industry. Sinter printing embeds and embosses colored powder into your cable jacket for a 100% permanent mark, ideal for highly corrosive or very abrasive environments. Taymer’s Sinter 3000 makes permanent makings on wire and cable without compromising the electrical or mechanical properties of the cable.

Taymer Advantages

Dual Print Drums Each With Dedicated Powder Reservoir

The Sinter 3000 comes with two print drums each with a high capacity powder reservoir. The two print drums allow you to print on two sides of your cable simultaneously. You may also use a non-printing drum to print on one side of the cable.

Clean Process

The Sinter 3000 comes with a powerful suction to prevent the powder from being scattered and airborne. The vacuum is located directly after the powder is sprayed to remove the excess. This ensure a clean legible print and a healthy environment for the operators.

Print Segments

Print inserts are available in segments of any number of characters, or in individual characters allowing you to form your own words. The inserts can be installed at three or four locations around the full circumference of the drum at any desired location or spacing. Individual inserts are easily installed or removed or you can also remove the complete drum in a minute.

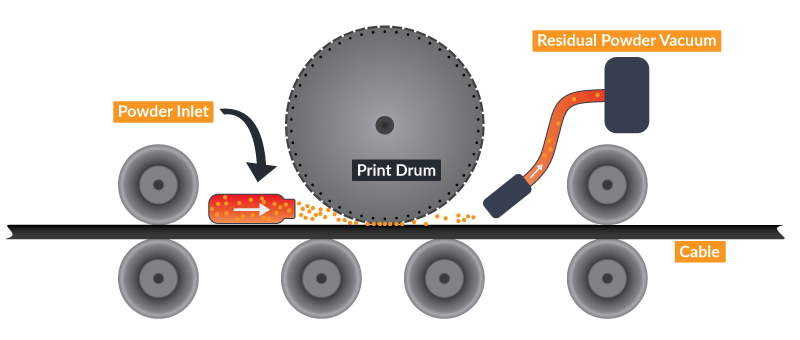

How it works

- This printing technology is to provide emboss printing with a colored powder.

- When the jacket is still soft after the extruder, the print drum (with emboss print head and inserts) creates an emboss print in the jacket.

- Powder is used to fill the sprayed onto the print drum.

- Once the inserts made contact with the cable, the ‘uncovered’ powder is vacuumed away.

- The powder consist of mainly material that makes up the jacket, such as polyethylene.

- After the powder hardens with the jacket, the colored print will become a permanent part of the jacket.

- This technology has been applied to the fiber-optic cable industry and provide excellent results.