CV2000

Color Verification

For Wire and Cable, Pipe and Conduit.

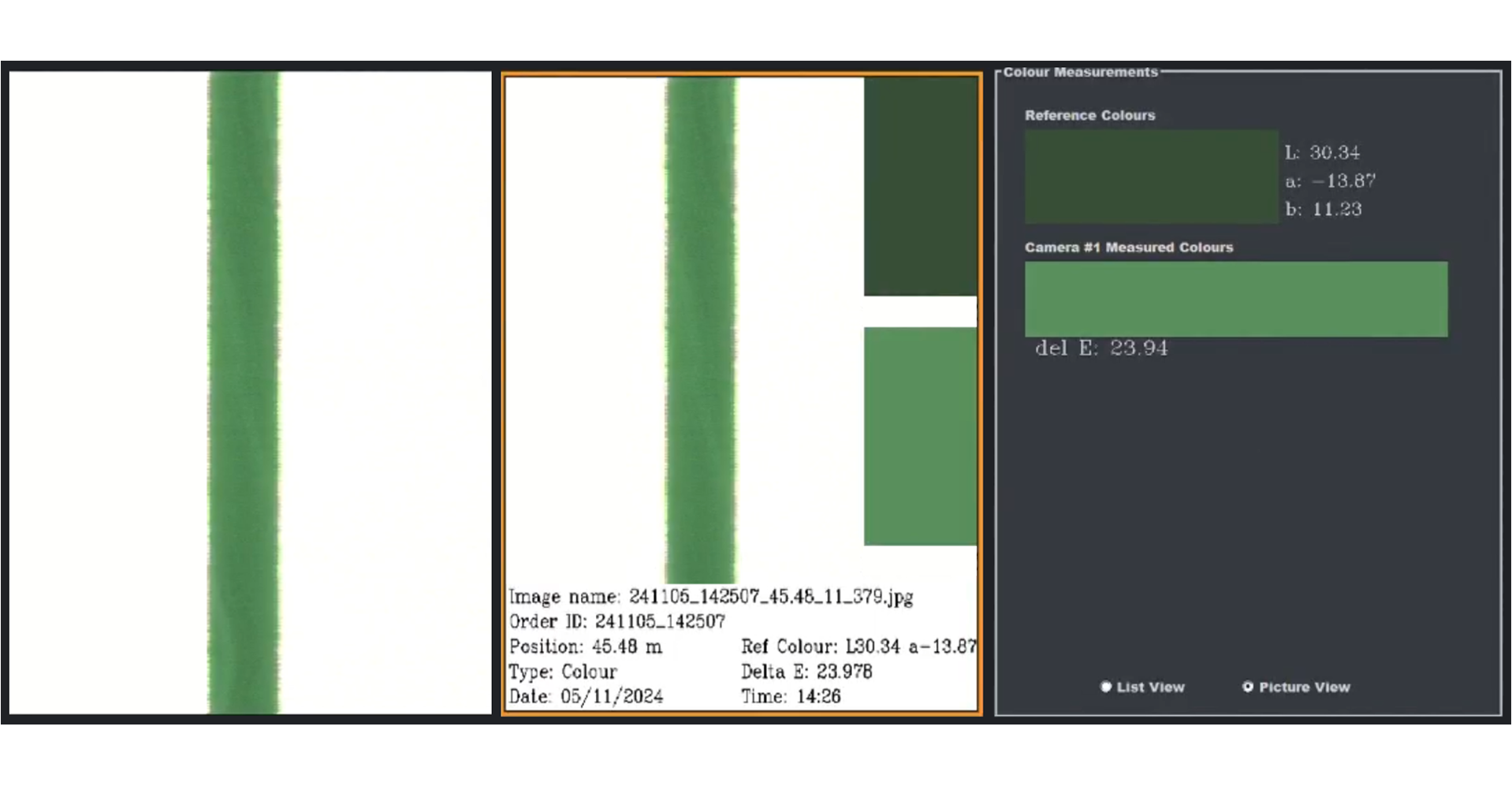

The Color verification system provides the operator with up to the second digital image feedback of the current color quality on any production line. This continuous stream of real time information allows the operator to monitor the color quality and gives time to react to correct coloring problems before they result in expensive rework or customer claims.

Increase Operator Productivity

The Color Verification system increases productivity in your wire and cable plant. Accurate data of the color quality allows operators to set-up production line quickly.

Quality Assurance

Using the color verification system, you can capture images of the colored cable, save the images to disk and print them out to include in your quality reporting both internally and to your customers. The system makes it possible for engineering and production supervisors to verify the color quality while briefly walking past the operator’s console.

Color Defect Detection and Alarm Option

The color verification system continuously monitors your cables using a combination of image processing software and algorithms to deliver accurate feedback on your color quality. The information is compared to target data to see if the color meets the specifications. If the color does not meet specifications, it will activate a solid-state relay to send a signal to alert your operator. This will save thousands of feet of color mismatched cable.

Features

- Allows accurate setup of color mixture

- Supports line speeds up to 3 000 meters per minute (9,800 ft./min)

- Alerts operator and production machinery for color anomalies

- Registers defects for quality control records and operator verification

- Continuous up-to-date section display of the jacket color, ensuring quality meets the target every time

- Optional remote-view station allows operators to catch undesirables while being at a distance from the unit

Specifications

- Maximum Line speed:

- 9,800 feet per minute

- 3 000 meters per minute

- Push Buttons:

- Light ON/ Light OFF

- Height Adjustment

- Computer Reset

- Capture Station Weight:

- Without stand: 10 lbs or 5 kg

- With stand: 50 lbs or 25 kg

- Operator Console Weight:

10 lbs or 5 kg

- Capture Station Dimensions (Without stand):

- 30″ X 22″ X 40″ (L X W X H)

- 760 mm x 560 mm x 1020 mm (L X W X H)

- Console Dimensions:

- 20″ X 20″ X 24″ (L X W X H)

- 510 mm x 510 mm x 610 mm (L X W X H)

- *Custom stands can be built*

- Stand Mount:

Height and Depth Adjustable - Inputs:

Length Measuring Encoder - LCD Display:

15″ - Calibration:

Easily programmable using standard keyboard - Power:

- 115 VAC 50/60 Hz

- 230 VAC 50/60 Hz