Cable Diameter Measurement

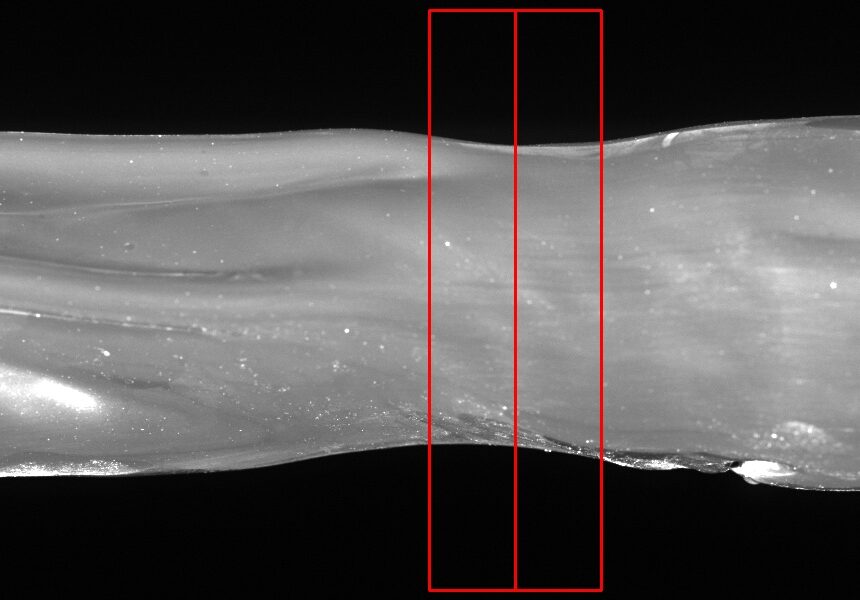

Taymer’s diameter measurement solutions play a crucial role in ensuring accurate quality inspection for a wide range of continuous products. These systems precisely measure the diameter of your product, detecting defects such as lumps, neck-downs, and other irregularities in real time. By utilizing advanced vision technology, our inline solutions allow operators to quickly identify and locate defects without the need to rewind miles of material, saving both time and resources.

Taymer’s innovative image-viewing software captures and analyzes diameter measurement variations with high precision. The system automatically saves images along with their dimensional data, making it easy for production teams to track, review, and address any product imperfections efficiently. With Taymer’s inline solutions, manufacturers can enhance quality control, reduce waste, and improve overall production efficiency.

Contact us for more information!

LN3800

Diameter Measurement and Lump Neck-Down Detector for Cable and Tubes

Taymer’s 3-camera lump and neck-down detector is a powerful cable diameter measurement solution that captures high-resolution images of defects and saves them with precise dimensional data. This advanced system provides a comprehensive view of your product, allowing for accurate defect detection and classification. With Taymer’s image-viewing software, operators can analyze cable diameter measurement variations in real time, ensuring that even the smallest inconsistencies are identified and addressed. As a result, you can take your quality control to the next level, reducing waste, improving production efficiency, and maintaining uncompromised product integrity for cable and wire manufacturing.

ZT5000

High-Speed Diameter Measurement for Fiber

Taymer’s high-speed lump and neck-down inspector is a cutting-edge diameter measurement solution designed specifically for the fiber optic industry. This advanced system is the only tool capable of capturing real-time images of defects during high-speed production, ensuring precise quality control. By providing instant visual feedback, operators can quickly determine whether a detected diameter measurement variation is a true defect or a minor fluctuation. Its high-speed capabilities make it ideal for fiber optic manufacturing, where precision and efficiency are critical.