Hot Foil Marking Machines

Taymer’s hot foil printing technology is ideal for bright, clear, high quality cable marking on tough-to-mark-on surfaces like Cross Linked Polyethylene, Nylon and Teflon. Hot foil printing is a very durable method of cable marking, well suited for outside plant cable marking. Due to the flexible design, some models can print on top and bottom of the cable as well as metric and footage.

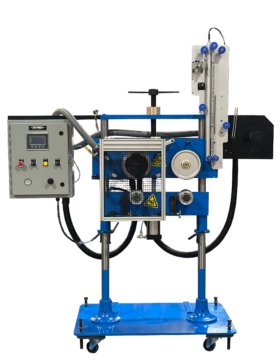

HF100

Hot Foil Marker for Pipes

Hot foil printer with sequential marking for pipe. Metric and Footage versions are available upon request.

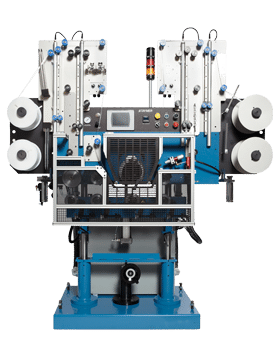

HF500

Hot Foil Cable Marker – Imperial

This cable hot foil printer includes a 6-digit sequential print head, as well as a two-foot print drum.

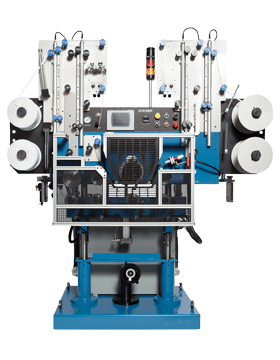

HF600

Hot Foil Cable Marker – Metric

The cable metric hot-foil printer includes a 1 meter print drum equipped with a sequential head.

HF2000

Metric & Imperial

This hot foil printer prints in metric and imperial measurements. Prints can be made in increments of 1 meter or 2 feet. The mechanical accumulator system reduces tape breakage through tape tension reduction. Extra cable guides ensure consistent print quality.

HF3000

Top & Bottom Hot Foil Printer

The HF3000 accurately prints simultaneously on both the top and bottom of a cable. All types of measurement options are available, including metric, imperial, and combined imperial and metric models. Its industry leading design minimizes maintenance requirements.

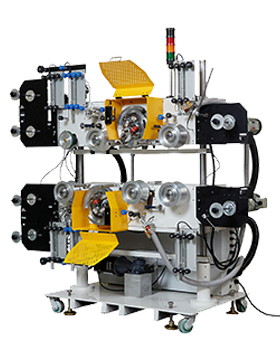

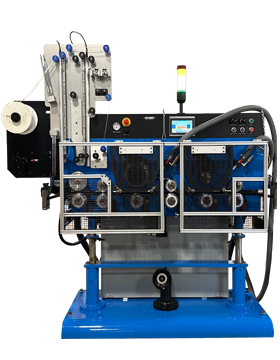

HF4000

Hot Foil Dual Drums Printer

The HF4000 includes an additional print drum for changing legends or switching between metric and footage printing. You can choose between footage, metric, or combined footage metric models. It is designed for printing without any interruption in production.

Hot Foil Tape

We also offer a wide selection of hot foil tape for use with hot foil printers. Available in various lengths and colors, our high-quality tapes are designed to meet your specific printing needs, ensuring optimal performance and vibrant results.

Get in touch with our sales team to find out more.

Taymer Hot Foil Advantages

Reduced Tape Consumption

The hot foil printer reduces tape consumption through a combination of the servo driven print drum and the vacuum air accumulator tape management system. The end result is the print wheel is in contact with the product only when the print message needs to be printed. This unique design often reduces tape consumption by 50%.

Multiple Hot Foil Tape Colours

Hot foil tape can come in a variety of different colors. Some colors include red, yellow, blue, green, white, and black. This variety allows cables to be printed with a color stripe for color coding purposes.

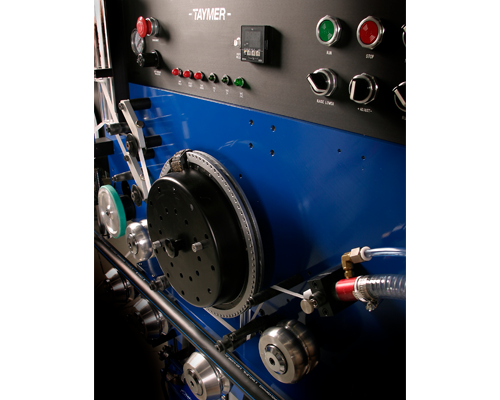

Safety Guard

The Taymer safety guard allows the operator to easily thread and rethread tape without raising the guard or stopping the printer. The safety guard locked to raise unless the printer has stop ensuring operators safety. Furthermore, it requires absolutely no maintenance, always safeguarding your operators. locked to raise unless the printer has stop ensuring operators safety.

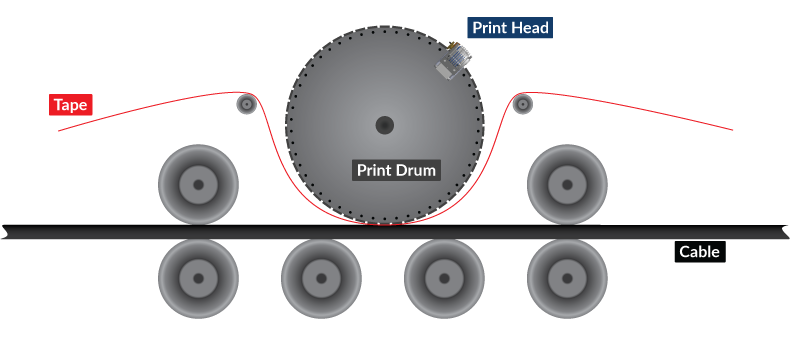

How it works

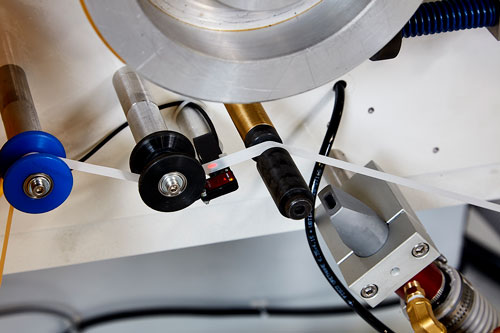

- To print on cables, the operator sets up the print drum with print inserts and a print head and the hot foil tape.

- The print drum will heat up according to a set temperature.

- As the cable is passing through the printing area, the print drum (with print head and inserts) are rotating at a relative speed.

- At the point of contact between the print drum and the cable, print characters are transferred onto the cable by heat-pressing through the colored hot foil tape.

- Depending on the pressure, an indent is usually formed on the cable as well, giving a permanent colored print on the cable.

- The used part of the hot foil tape will advance forward and would not be used until the next set of prints. As for the print head, it will advance automatically to the next number.

- This printing cycle can happen at a rate of 600 feet / minute.