Fiber Optic Inspection Equipment

Dirty or damaged fiber optic connectors are some of the most common optical network problems. Many businesses rely heavily on optical fiber cabling, therefore being able to test its quality to ensure network performance can be critical.

Taymer International has a wide range of fiber optic solutions that will help ensure you have the ability to troubleshoot any broken links.

Ongoing testing and maintenance of fiber optic networks is paramount and will lead to more efficient and reliable fiber optic network deployment.

Solutions for Fiber Optics

Taymer provides advanced vision systems for defect detection in fiber optic product manufacturing. Our solutions are engineered to inspect and verify critical features in fiber optics, including marking bands, color sequence, and planarity on ribbons, as well as dimensional control of glass preforms and fiber strands.

Our fiber optic inspection equipment allows technicians to accurately inspect fiber end-faces for contamination, ensuring optimal performance and reliability. Additionally, our unique band inspection tool is the only system available for automatic quality inspection on coloring lines.

Whether for installation or maintenance, our fiber optic inspection tools help identify defects and ensure efficient network performance. If you’d like to learn how our technology can support your fiber optic manufacturing needs, contact us today to speak with one of our engineers.

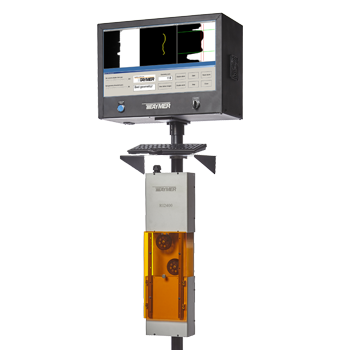

BI1800

Band Inspection System

The BI system is the only tool available to automatically inspect band quality on fiber and small wire lines. This will help you reduce costs in your production facilities through reduced rework and quality assurance.

GS2100

Camera Inspection for Glass Fiber Preform

The only tool that can continuously measure the glass preform rod for fiber optic cables during the stretching process to ensure the resultant preform diameter is both consistent and accurate.

RI2400

Fiber Ribbon Inspector

The Ribbon Inspector’s continuous capture mode of operation provides the operator with up to the second digital image feedback of the current status of the fiber optic ribbon.

ZT5000

High Speed Diameter Measurement and Lump Neckdown Gauge

The High-Speed Lump and Neckdown Inspector is the only tool that can provide images of your lumps and neckdowns on: bare wire and fiber.