PV4500-Snapshot

High Speed Print Inspection

The PV SnapShot provides high speed, automated print inspection for continuous processes especially wire, cable, pipe, tube, hose and conduit. This will help you reduce costs in your production facilities through reduced rework and improved productivity.

The PV SnapShot 4500 uses a high-speed, color digital imaging system to capture real time images of cable markings. The digital images are enhanced, magnified and displayed on a monitor, enabling the operator or our “No Print Detector” to properly set up and monitor cable printers before poor print causes expensive waste.

The operator’s console can be located up to 200 feet or 60 meters from the Image Capture Station, allowing one operator to supervise two or three lines simultaneously.

Features

- Captures Line Speeds as fast as 5000 ft/min or 1500 m/min

- Detects if print legend is missing from cable

- Unique technology removes cable twist from images

- Characters as small as 0.030″ or 0.75mm, can be frozen, magnified and easily read

- Displays print from any printer including: Inkjet, Ink Wheel, Hot Foil

- ‘Save Image’ feature provides complete Quality Assurance documentation

- Includes verification tool for sequential markings

- Simple, Push Button Operator Interface

- Small Footprint, LCD, Flat Panel Display

Automatic “No Print” Detection

This option adds software and a relay to your Print View allowing automatic, continuous inspection of print. If there is a “No Print” condition detected, a signal will be sent to your machinery or an alarm to alert the operator.

Remote Operator Console Extension

This signal strengthening extension allows you to locate the operator’s console 90 meters and further away from the capture station. This option includes a signal splitter, a signal strengthener and 90 meters of video cable.

Reduced Printing Rework

The Print View 4500 SnapShot’s Continuous Capture mode of operation provides the operator with up to the second digital image feedback of the current print quality on any production line. This continuous stream of real time information allows the operator to monitor the print quality and gives him or her the time to react to correct marking problems before they result in expensive cleaning and reprinting or even scrapping of product.

Increased Operator Productivity

The Print View increases productivity in your wire and cable plant. Continuous feedback of print quality allows operators in a single, central location to supervise more than one production line simultaneously, freeing up personnel for other functions.

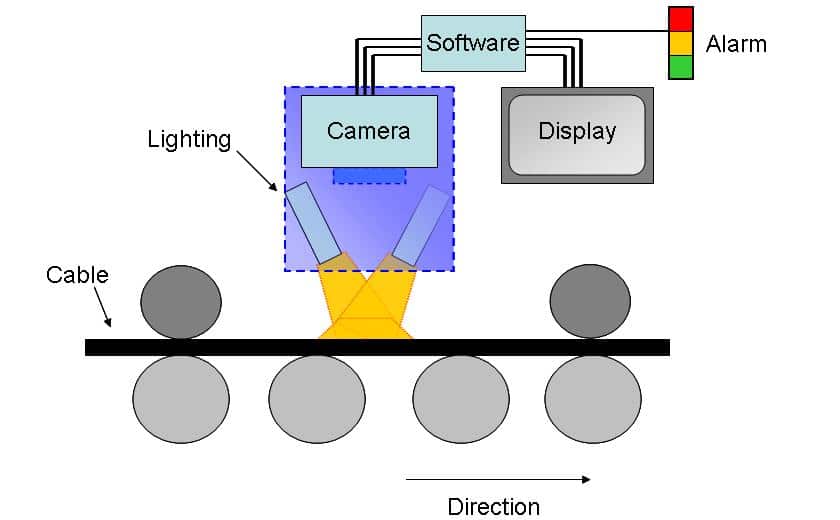

How it works

- The high-speed camera optical system consists of a high speed camera and adequate lighting to capture images of cable moving at 4500 feet/min.

- An encoder synchronizes the camera capture rate and the cable speed.

- Software will then enhance, magnify, and display the images on a monitor

- An algorithm is used to process the images for print detection.

- If there is a ‘No Print’ condition, an alarm will notify your operator and an error report is saved to the ongoing data log.

Specifications

- Maximum Speed:

5000 feet per minute (1500 meters per minute) - Character Size:

0.030″ – 0.500″ (0.75 mm – 12 mm) - Push Buttons:

- Scroll Left/Right

- Freeze Image

- Save Image

- Brightness

- Capture Station Weight:

- Without stand: 10 lbs (5 kg)

- With stand: 50 lbs (25 kg)

- Operator Console Weight:

10 lbs (5 kg)

- Capture Station Dimensions:

- Without stand: 30″ x 22″ x 40″ (760mm x 560mm x 1020mm) (L x W x H)

- With stand: 32″ x 24″ x 70″ (815mm x 610mm x 1780mm) (L x W x H)

- Console Dimensions:

20″ x 20″ x 24″ (510mm x 510mm x 610mm) (L x W x H) - Stand Mount:

Height and depth adjustable - Inputs:

Length measuring encoder - LCD Display:

15″ - Calibration:

Easily programmable using standard keyboard - Power:

- 110 VAC 50/60 Hz

- 220 VAC 50/60 Hz