IWCS 2015 – Optical Wrap Defect Inspection for Cable

October 23, 2015IWCS 2014 – Optical Surface Inspection with Accurate Diameter Measurement

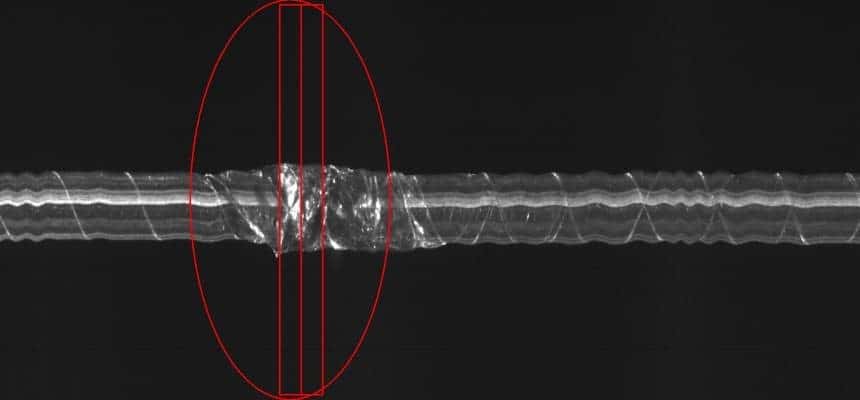

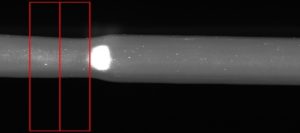

Figure 1. Bulge

Optical Surface Inspection with Accurate Diameter Measurement

Mr. Craig Girdwood, Mr. Andrew McCloskey

Taymer International Inc., Markham, Ontario, Canada, +1-905-479-2614

Abstract

The use of optical surface inspection with accurate diameter measurement greatly improves quality control of wire and cable. The surface and diameter of the wire or cable is continuously monitored by a machine vision system at production line speed. The diameter measurements are able to be viewed live and/or recorded for 100% of the cable length. Surface and diameter defects are identified, and images of the defects are recorded together with position information. This technology improves the quality of the cable produced and greatly reduces defective products from reaching the customer.

Introduction

A significant quality issue created during the production of wire and cable is surface and diameter defects including: pinholes, blemishes, neck-downs and bulges. These defects are not only a cosmetic problem, but they can lead to the core being exposed to the surroundings, resulting in short circuits and failure of equipment. Through the identification and detection of these defects during production, corrective action is able to be taken and defective pieces can be discarded. With the constant and immediate feedback from the machine, operators and process engineers are able to pinpoint the root cause of the defects.

The Surface Defect Detection System contains multiple cameras capturing real-time images of cable surfaces at high-speed. The SDD software is able to accurately measure the diameter of the cable, as well as determine both the type and size of a wide range of surface defects. Diameter variances as low as 0.05mm can be measured for cables with diameters from 0.6mm to 5mm. Surface defects as small as 0.1mm can be detected and an alarm triggered. When a defect is detected a digital image is enhanced, magnified and displayed on a remote monitor, enabling the operator to verify the defects. This allows operators to determine the type of defect, to identify false positives (i.e. a water droplet), or even detect surface blemishes (i.e. surface discoloring, scratches).

The diameter measurements for the entire cable are saved to a database along with a record of any diameter or surface defect information. The defect information includes defect type, size and location on the cable in meters or feet. This allows defects to be isolated quickly by operators after production is completed.

The Surface Defect Detection system is able to be easily integrated into existing production lines and performs well for any type of cables, including armored, jacketed, bare wires, and convoluted profiles. The SDD System makes sure that any problems are discovered prior to any defective products are sent to customers.

The lifetime of the lights can be over 50,000 hours of usage and they are the only consumable part. The unit can also be adapted to different applications – bare wire, cables, hose, pipes, tubing, braided coverings, stranded members and other surface inspections.

Current Defect Detection Technique and Diameter Measurement Limitations

Laser Diameter Gauges

A laser diameter gauge is used to measure diameter and detect bulges, neck-downs. The machine uses a laser and shadow technology to measure the diameter of the cable. The diameter measurement is extremely accurate and can be used to classify bulges or neck-downs. However, from just the laser gauge information there is no way to truly know if the defect detected is an actual defect. For example, a dust particle or water droplet on the cable would increase the diameter measurement, resulting in a false positive. Laser diameter gauges can also have trouble measuring the diameter of transparent materials.

Spark Tester

A spark tester is equipment that can be used to detect pinhole-type defects. The machine creates a spark when there is a pinhole that exposes the core of the cable – conductive metal. However, if a pinhole does not expose the core, the spark is not created. But the pinhole that is not a through hole is still a defect since over time, the pinhole could expand and expose the core of the cable. As well, for products without a core (pipe, hose, tubing) or products without a conducting core (fiber optic cable) spark testers are not applicable.

Vision Systems

Previous configurations of surface defect detection systems were unable to accurately measure cable diameter due to vibrations in the cable changing the relative size of the cable in the field of view. These systems were limited to observing relative changes in diameter such as a bulge or neck down. The surface inspection system has been improved with a new series of optics technology that fixes the cable in the field of view to be able to get accurate diameter measurements.

Machine Vision Inspection System

Optical Mechanical Design

The surface defect detection system with accurate diameter measurement consists of multiple high resolution cameras and adequate lighting to capture images of cable moving at speeds more than 1200 feet (400 meters) per minute. Accurate diameter measurement is achieved by improving the optics technology in one or more cameras to keep the cable as a fixed size in the field of view.

The multiple cameras provide 360 degree coverage of the cable surface. The multi-camera system produces high quality images at these speeds by at a very high frame rate. The frame rate is synchronized with an encoder and speed algorithm.

The lighting varies depending on the application. The factors in consideration are the reflectivity of the material, surface profile, color, line speed and camera type.

To ensure consistency in the images, the setup features an enclosure to prevent ambient lighting, outside particles, etc from affecting the results. Vibration of the cable is minimized by wire guides, preventing images from being out of focus.

An advanced algorithm is used to process the images for surface inspection. A typical algorithm is capable of detecting cable surface defects such as surface blemishes, holes, neck-downs, and bumps. The algorithm requires analysis of the pixels of the image and grouping them for further interpretation.

If a surface defect is detected, an alarm will notify your operator and an error report is saved to the ongoing data log. The defect will also show up on the display for operators to clarify.

Improving Quality Assurance

Suitable for any type of Products

Since the surface defect detection system with accurate diameter measurement uses machine vision, it is able to be used inspect the surface for any type of products such as bare wire, cables, pipe, tube, and tapes. It is the most thorough method of detecting surface flaws available and the advanced algorithm can help classify the type of defects accordingly. The accurate diameter measurement technology is currently designed to measure cables with outer diameter ranges between 0.6mm to 5mm to an accuracy of 0.05mm.

Reduce Defects

The system can provide the operator with a view of current surface images as well as both the most recent surface defects with defect dimensions and the current cable diameter. This continuous stream of real time information – especially failure data – allows the operator to isolate the causes of jacket imperfections. Identifying when and how a defect occurs will allow the technical staff to learn the root cause of defects and reduce their occurrences.

For example, running the surface defect detection system at a number of facilities around the world has shown that surface defects are caused by:

- transitioning too soon to a new color

- the extruder screw being improperly cleaned

- poor quality compound

Understanding the source of defects allows cable facilities to eliminate the root causes of the defects by statistical measures.

Quality Assurance

The system will continuously and accurately monitor the diameter of the cable, and record the measurements for later analysis. Images of cable defects are captured and saved to a hard disk for use in quality reports. The Surface Defect Detection system’s display makes it easy for engineering and production supervisors to examine both diameter and defects without having to see the defect itself. Defect images and diameter measurements are saved together with location information allowing your operators to quickly find and eliminate defects before they reach your customers or fail in the field.

Limitations

There are a few limitations to the surface defect detection system.

- Sometimes significantly different cable surfaces (round vs convoluted vs figure 8) will require adjustment to the optical setup or software changes.

- Since the camera is looking at the surface, water droplets/ grease/ dust particles will be detected as defects by the system. Generally, this can be fixed with a well-placed air wipe. Alternatively, the system sensitivity can be decreased, which may result in some of the smaller defects passing through the filter.

Test Results

The Surface Defect Detection system has been tested in numerous production lines around the world. The addition of diameter measurement allows the SDD to record the diameter along the entire cable length, as well as detecting variances in the cable diameter.

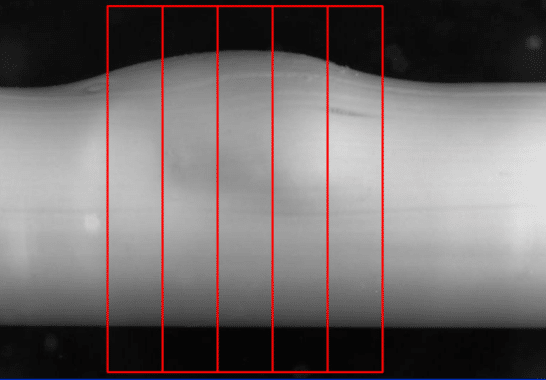

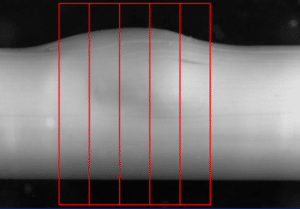

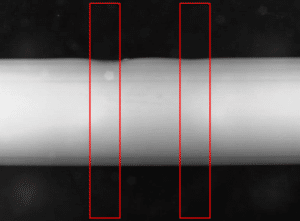

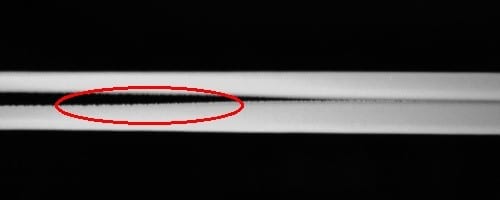

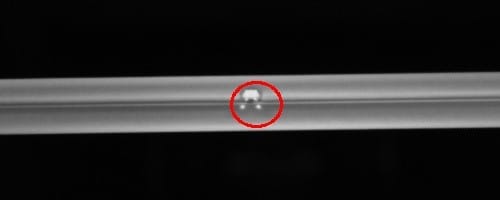

Some samples images of defects can be seen below from Figure 1 to 7.

Conclusions

With a surface defect detection system with accurate diameter measurement, both the imperfections of the cables will be detected and the diameter is accurately measured and recorded. The system provides several benefits.

- Suitable for any type of products – wire/ cable/ hose/ pipes/ bars/ plates/ stranded product

- Ensure the customer will not get defective products improving customer relationship and confidence

- Reduce rework and eliminate cable waste resulting in material cost and labor cost

- Assist in internal improvement to production process to reduce defects

Contact us today if you would like to discuss Taymer’s Optical Surface Inspection with Accurate Diameter Measurement technology further.