Need a quality control solution that will help maintain consistency in your wire or cable products? At Taymer, we provide a selection of innovative technologies designed to empower your facility operators and ensure excellent quality in your final products.

Taymer is proud to be providing our quality control and vision inspection equipment to Belgium, the Netherlands, and Luxembourg. From Brussels and Antwerp to Rotterdam and Groningen, manufacturers across the Benelux area are able to obtain premium quality control and inspection equipment to support their operations.

Contact our team today to find the quality control and inspection solutions for your manufacturing needs.

Contact our team today to find the quality control and inspection solution you have been looking for.

Length Measurement Equipment for Cable & Wire Products

Achieve consistency in your wire and cable products with Taymer’s length measurement equipment. Built on over 30 years of experience and a passion for innovation, our cable and wire length measure machines use high-precision technology to assist your operators in detecting any inconsistencies in your product’s measurements.

Efficiency is a key advantage in using Taymer’s length measurement equipment, including our Length Rite series. Developed to perform at a variety of different speeds and equipped with digital integration, our cable and wire length measurement machines are able to give your operators instant insight into inconsistencies without any unnecessary slowdowns or interference.

Vision & Quality Inspection Solutions

Manufacturers across Belgium, the Netherlands and Luxembourg can guarantee integrity in their cable, wire and other continuous products with our vision inspection equipment. Our machines have been developed to precisely detect neckdowns, lumps or other variations in the product’s surface. Our machinery will help your operators to identify and remove any flawed products while also helping to improve your overall manufacturing performance.

Our vision inspection equipment easily works with a variety of continuous products, including:

Metal

Our vision inspection machines will detect and capture flaws in metal products such as bars, bare wires and stock . Thanks to our innovative superior photographic imaging, your operators will be able to get precise imagery of any flaws detected. These images can easily be analyzed and shared with other operators and teams, helping you strengthen and align your quality control processes.

Medical

Our vision inspection equipment works seamlessly with medical products such as medical tubing and catheters. By inspecting and capturing each square millimetre of your product, our machines will help you detect flaws invisible to the naked eye including bubbles, gels and inclusions that would otherwise compromise the overall product quality and appearance.

We also provide a range of other quality control solutions for medical products, including our pill inspector and counter.

Find out more about our medical product inspection solutions.

Fibre Optic

Fibre optic manufacturers in Belgium, the Netherlands or Luxembourg can upgrade their cable inspection process by utilizing Taymer technology. Our fibre optic inspection equipment and machinery is designed to support your operator’s quality assurance process by detecting and capturing inconsistencies in key characteristics such as band quality and inner and outer diameter measurements at different stages of the stretching process.

3D Printing Filament Inspection

3D printers offer product designers and innovators an excellent opportunity to realize their creativity and ingenuity. However, faulty or defective 3D printer filament can easily compromise their efforts by causing costly printer blockages or subpar products.

By utilizing Taymer technology, 3D printer filament manufacturers can produce consistent, premium-grade products. Our 3D printer filament inspection equipment will scan and capture any potential defects that could compromise the integrity or quality of the filament, no matter how small they may appear to be.

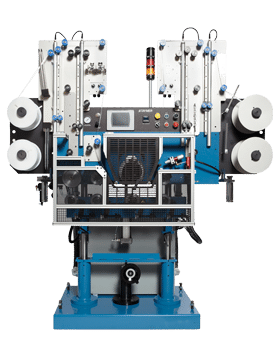

Wire & Cable Printing Machines

Produce high-quality wires and cables with exceptional printwork thanks to our cable and wire printers. Tailored to operate at a variety of speeds, our cable and wire printers deliver colourful, clear and concise printwork that will demonstrate your brand’s high standards and remarkable attention to detail to your customers and regulators.

Our wire and cable printers are specialized in a range of printing techniques, including:

-

-

-

-

- Hot Foil Marking

- Hot Stamp Wire Marking

- Emboss & Indent Printing

- Sinter Printing

-

-

-

Discover more about our wire and cable printing technology here.

Contact Us

To discover more about purchasing our quality control and vision inspection solutions for your manufacturing facility in the Benelux area, please contact our sales team.

Taymer Europe GmbH

Groeningenweg 16/0011

Diepenbeek 3590

Belgium

Email: [email protected]

Phone: +32 492 44 94 44