LR600 Automated Pull Measure Cut Technology for Wire and Cable

The LR600 Pull Measure Cut System incorporates everything necessary to automate the rewinding line. The system comes in scalable sizes and benefits users from small harness facilities to large cable manufacturers. The fully automated LR600 PMC incorporates a payout system, a length-rite measurement device, an automated cutting system, and a take-up system (coiler/spooler). The PMC system will save time, reduce space taken on your production floor, and increase productivity.

Features

- Dedicated, easy-to-read, digital cable counter and line speed display

- State-of-the-art electronics system allowing for multiple inputs and outputs

- Highly accurate +/-0.05%

- Pneumatic raise and lower of the encoder assembly

- Height adjusts for varying line heights

- Easy belt removal and installation

- Stepper motor to pull wire through the length rite

- Cut options (automatic, pneumatic, hydraulic, or chop saw)

- Connect to a PLC to maximize cable counter function flexibility

- Integrated Despooling and Recoiling option

Advantages

Automate with Batch Job Programming Tools

-

- Jobs can be identified by a job number or the operator can simply input the length of cable required and the quantity of cut cables required and then press ‘Start’

-

- PLC technology is used to maximize cable counter function flexibility – we can include an HMI to make data entry easy

Customized to your Needs

-

- Taymer is willing to customize our systems to suit your needs

-

- We will modify the set-up or system according to your application, to make our equipment easy-to-use and work the way you wanted it to

-

- We provide this great flexibility to minimize your time to search for the right products

Integrated Pull-Measure-Cut Option

-

- The Length Rite Pull Measure includes a stepper motor to pull wire through the Length Rite

- The Cut option may be included to allow automatic, pneumatic, hydraulic, or chop saw cutting of wire and cable with diameters up to one inch or 25mm

Connect with a Computer

-

We work regularly with Allen Bradley, Siemens and GE PLCs and can include communications capabilities for corporate networks or standalone PCs through ethernet or serial communication ports

-

Taymer’s cable cut to length computer interface simplifies the task of uploading and cataloging long lists of batch jobs

-

We are familiar with MS Access, MS SQL Server and MS Excel for inputting batch job data

Integrated Despooling & Recoiling Option

- Larger spools of wire and cable will require a motorized despooler to accurately pull & recoiling-through the Length Rite & Cutting Saw

- Taymer’s Despoolers handle cable reels from 50lbs to 5500lbs

- Smaller reels generally don’t require a despooler.

- It also includes a dancer or tension arm, minimizing the tension force required to pull the cable through the Pull-Measure-Cut

- The system will wait for operator to push the go button before payout of the next length in the PLC cue, or the next new length entered

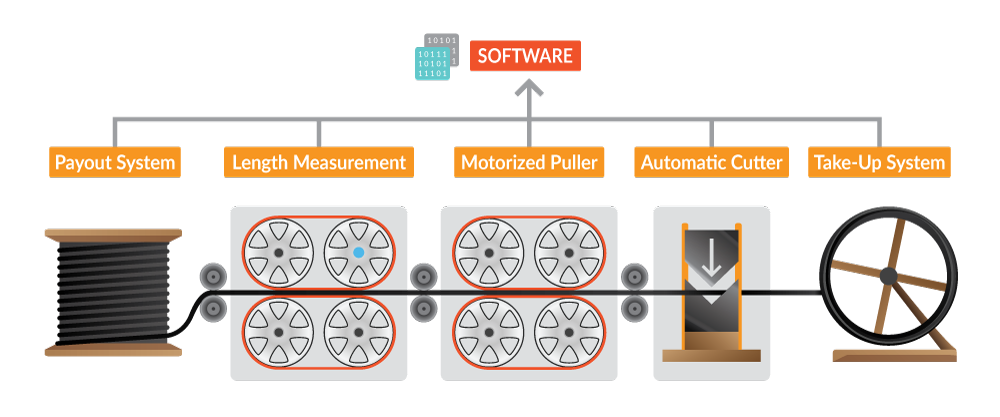

How it works:

-

-

- A payout system is to unload the bulk wire or cable whether it is in the form of a spool or a coil.

- For heavy spools or coils, a motorized payout system might be necessary in order to prevent damage to the wire/ cable under high pulling tension.

- The wire / cable will go through a measurement device for accurate measurement.

- At this station, the operator or computer can assigned a target length so when the measurer reaches the length, a control system will stop the cable movement.

-

-

-

- This will lead to an automated cutter that cuts the wire.

- To pull the wire, there are two methods:

→ If the wire does not need to be coiled or spooled, then a motorized puller is located before the cutter to pull from the payout.

→ If the wire needs to be spooled or coiled, a take up system is required. - The take up system is motorized and will spool or coil accordingly.

-