PV1400

Print Verification

The Print View 1400 is the only tool available for operators to completely verify and guarantee print quality on high speed production lines. This will help you reduce costs in your production facilities through reduced rework and improved productivity.

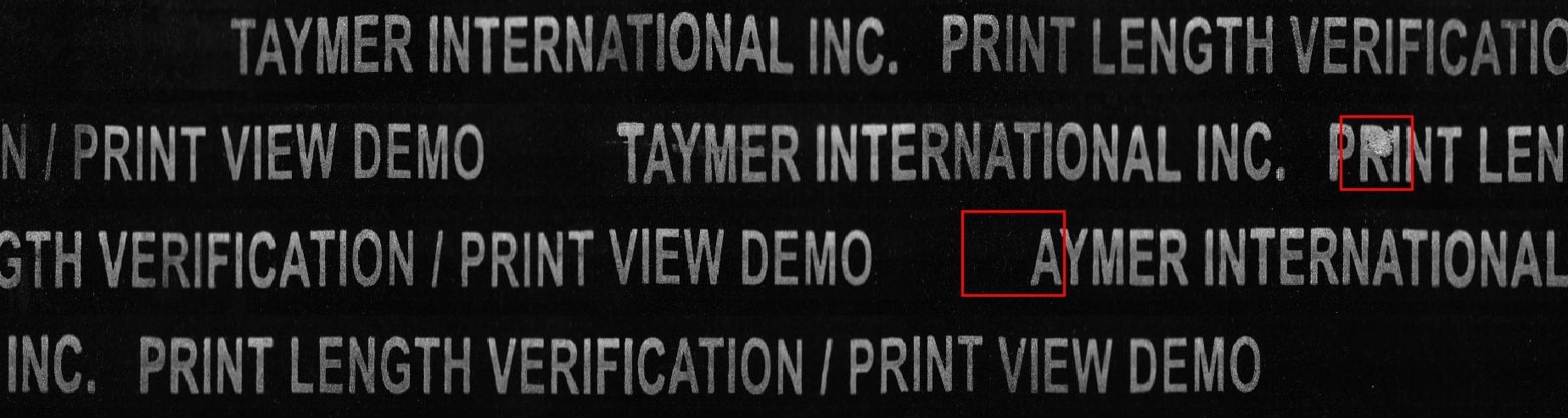

The Print View 1400 uses high-speed, digital imaging to capture real time images of cable markings. The digital images are enhanced, magnified and displayed on a monitor, enabling the operator to properly set up and monitor cable printers before poor print causes expensive waste.

The operator’s console can be located up to 200 feet or 60 meters from the Image Capture Station, allowing one operator to supervise two or three lines simultaneously.

Features

- Captures Line Speeds as fast as 3,200 ft/min or 1,000 m/min

- Unique technology removes cable twist from images

- Characters as small as 0.012″ or 0.3 mm, can be frozen, magnified and easily read

- Verifies print quality of any printer including: Inkjet, Ink Wheel, Hot Foil

- ‘Save Image’ feature provides complete Quality Assurance documentation

- Includes verification tool for sequential markings

- Simple, Push Button Operator Interface

- Small Footprint, LCD, Flat Panel Display

- Guaranteed accuracy of print legends

- Improved traceability through the verification of date codes and sequential markings

- Instantaneous error notification without additional setup requirements for the operator

Optical Character Recognition (OCR)

By incorporating OCR into the PV1400, Taymer has revolutionized real-time quality control for the production line. OCR converts print legends into a machine readable format which can then be analyzed to assess quality, accuracy, and legibility. This advanced machine learning model is capable of recognizing a diverse range of languages, fonts and styles. This highly adaptable solution is suited for any type of printer, and will perform consistently and reliably across various printing methods.

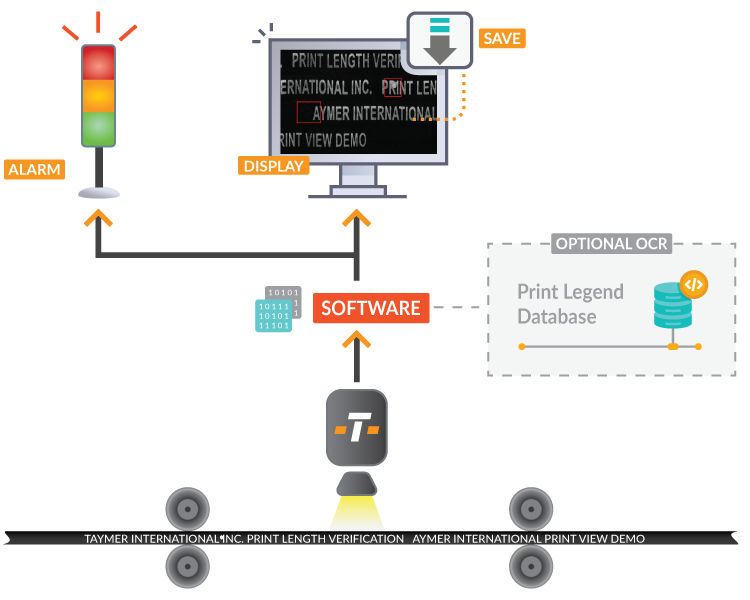

Automatic Print Quality Detection and Alarm Signal

This enables your Print View to read and validate the legend being printed on the cable compared to a known good print set by the operator at the beginning of the run. If the Print View detects poor quality or missing print, a signal is sent by the Print View to alert the operator.

Cable Twist Compensation

The Print View uses two unique technologies to take the twist out of cable legends, allowing the operator to read the printed legend even more clearly and easily than reading a stationary cable. The cable image is built on screen using a combination of a mechanical and software technology, effectively removing the constant wire and cable twist.

Sequential Numbering Accuracy Check

The Print View utilizes an encoder to calculate length measurements which are then displayed on the operator’s console together with the sequential measurement markings being printed on the cable. This allows the operator to quickly and easily compare the printed sequential numbers with the actual sequential measurements. Simple verification allows operators to take corrective action before thousands of feet of cable are marked with incorrect length information.

Cable Scan Software

The CableScan option stores up to 30,000 images in an image library. The cable legend images can then be quickly searched (fast forward and rewind functions are included) to find the exact location where cable print began to deteriorate. CableScan can be set up to save one image per two-ten meters of cable. This will allow you to store up to 300 km of cable legend before clearing the image library.

The Print Verification Inspecting Print Defects

Optical Character Recognition

How it works

- The high-speed optical system consists of a high resolution camera and adequate lighting to capture images of cable moving at high speed.

- The adjustable setup is designed to accommodate various cable size and print locations.

- Software will then enhance, magnify, and display the images on a monitor.

- An algorithm is used to process the images for print inspection.

- Print inspection involving detection of print, print quality, character verification are performed.

- If the print is worse than the operator-defined condition, an alarm will notify your operator and an error report is saved to the ongoing data log.

Specifications

- Maximum speed:

- 1 000 m/min

- 3,200 ft/min

- Character Size:

- 0.3 mm and up

- 0.012″ and up

- Push Buttons:

- Scroll Left/Right

- Freeze Image

- Save Image

- Brightness

- Capture Station Weight:

- Without stand: 10 lbs (5 kg)

- With stand: 50 lbs (25 kg)

- Operator Console Weight:

10 lbs (5 kg) - Install Location:

Immediately after printer

- Capture Station Dimensions:

Without stand:

-

- 30″ x 22″ x 40″

- 760 mm x 560 mm x 1020 mm

With stand:

-

- 32″ x 24″ x 70″

- 815 mm x 610 mm x 1780 mm

- Console Dimensions:

- 20″ x 20″ x 24″

- 510 mm x 510 mm x 610 mm

- Stand Mount:

Height and Depth Adjustable - Inputs:

Length Measuring Encoder - LCD Display:

15″ - Calibration:

Easily Programmable using standard Keyboard - Power:

110 VAC 50/60 Hz or 220 VAC 50/60 Hz