PV150-PH

Packaging Label Inspection

The PV150-PH is Taymer’s Print Verification solution for the packaging industry. The system will verify print quality for labels and packaged products. For instance the unit is capable of rejecting missing code dates or improper bar codes. Reduce production cost by avoiding rework or recalls and improve productivity with our PV150.

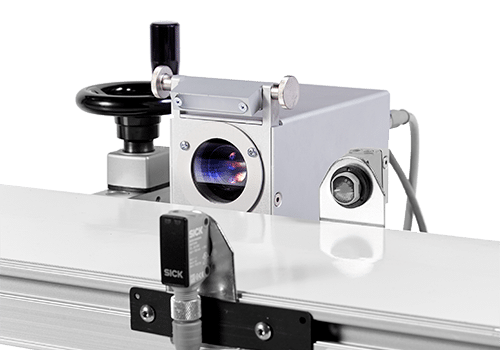

The Packaging print verification system uses a high speed, digital imaging to capture real time images of your product labels. The digital images are enhanced, magnified and displayed on the control console for easy operator use.

Taymer’s PV150 includes an automatic print quality inspector. This feature continuously compares the current label image to the image taught to the system by the operator at the beginning of the run. The template can easily be set by the push of a button on the touchscreen console. When any small changes in legend and print quality are detected, the PV150 will send a signal to external alarms, blowers or any other equipment on the line. The operator console and stand are modular and can fit in various line structures. The system can also be integrated to other in line equipment allowing the operator to easily supervise multiple processes.

The PV150 includes options such as stainless steel production for clean room requirements and I.P. sealing for easy maintenance. The system can be placed inline or used offline.

Contact us to discuss your specific application.

Features

- Character segmentation, recognition and verification technology

- Print Quality Inspector sends alarm signal to alert the operator

- Verifies print quality of any printer type (Inkjet, Hot Stamp, etc)

- Real-time display of errors

- Classification of errors by type for ease of correction

- Non-Contact Verification

- Verification of bottle and bundle serial numbers

- Quality Assurance reporting and documentation

- 100% line inspection

- Modular lighting for a variety of packaging colors

- Report for end of batch summary

- Defect images are saved on cpu for later use or audit

- Simple, touch screen operator interface

- Create and save unlimited recipes

- Small footprint, LCD, flat panel display

- ESAFE Certified

- Works with any line speed

Specifications

-

- Characters:

- 0.75mm – 12mm | 0.030” – 0.500”

- NDC/DIN, Expiry Date, S/N, Labels, etc

- Integration:

- Package Tracking

- Package Rejection

- Package Rejection Confirmation

- Flexible multi sensor trigger and confirmation options

- Line Stop

- PLC integration not required

- Defects:

-

- Serialization

- Print Verification

- Print Quality Inspection

- Label Presence

- Label Orientation

- Ingress Protection (IP) Sealing

- Color Verification

- Defect classification (ie. Lot Defect, Missing Print, Expiry Defect) in reporting

- Line Speed:

- Easily programmable using standard HMI

-

- Characters:

-

- Machine Modularity:

- Alternative lighting solutions

- Optional additional cameras

- Flexible mounting options

- configurable alarms

- Certification:

- ESAFE

- Calibration:

- Easily programmable using HMI

- Weight:

- 91 kg / 200 lbs

- Capture Station Dimensions:

- 72 mm x 75 mm x 150 mm – L x W x H

- 2.83″ x 2.95″ x 5.90″ – L x W x H

- Stand Mount:

- Height and depth adjustable

- Power:

- 115 VAC 50/60 Hz

- 220 VAC 50/60 Hz

- Machine Modularity: